In industrial processes, managing superheated steam effectively is crucial for maximizing energy efficiency and process reliability. Desuperheaters have emerged as a critical solution for cooling superheated steam and returning it to its optimal, saturated state for heat transfer applications. Croll Reynolds, a company with over 100 years of engineering excellence, has developed advanced desuperheater systems that combine simplicity, reliability, and cost efficiency. These systems allow industries to reduce operational costs, avoid harmful chemicals, and achieve consistent performance in a wide range of applications.

How Desuperheaters Work

The primary function of a desuperheater is to cool superheated steam by introducing pressurized water directly into the steam flow. The water is atomized into very fine droplets using specially designed spray nozzles, creating a mist that mixes thoroughly with the steam. As the water droplets evaporate, they transfer heat to the superheated steam, lowering its temperature and returning it to a saturated state. This method of heat transfer is highly efficient, requiring no moving mechanical parts, which makes the system remarkably reliable and easy to maintain.

Low Maintenance Benefits

One of the standout advantages of desuperheaters is their minimal maintenance requirements. Because the system operates without moving parts, there are fewer mechanical components to wear out or fail over time. This reduces the risk of downtime and the need for frequent repairs, making it ideal for industrial processes that demand continuous, reliable operation. Spray nozzles are the primary maintenance items, and they are typically durable and easy to service. The simplicity of the design allows plant operators to focus on other critical aspects of their systems without worrying about complex maintenance schedules or costly mechanical repairs.

No Chemicals or Refrigerants

Another significant advantage of desuperheaters is that they operate using only water, eliminating the need for chemicals, refrigerants, or absorption solutions. Many traditional steam cooling methods require chemical additives or lubricants to function effectively, which can increase operational costs and pose environmental risks. Croll Reynolds’ desuperheater systems avoid these complications, providing a cleaner, safer solution for industries concerned about sustainability and regulatory compliance. By relying solely on water for cooling, these systems reduce potential contamination, simplify operations, and support environmentally responsible practices.

Cost Savings and Operational Efficiency

Desuperheaters also contribute significantly to cost savings and overall operational efficiency. The low initial investment, combined with minimal maintenance costs, ensures that companies can achieve a quick return on investment. Additionally, by efficiently returning superheated steam to its saturated state, these systems improve the performance of downstream heat transfer equipment, reducing energy waste and increasing process efficiency. Industries using Croll Reynolds desuperheaters often see lower operating expenses due to reduced maintenance, elimination of chemical costs, and improved energy utilization, making the technology a smart choice for both new installations and retrofits.

Easy Integration and Flexibility

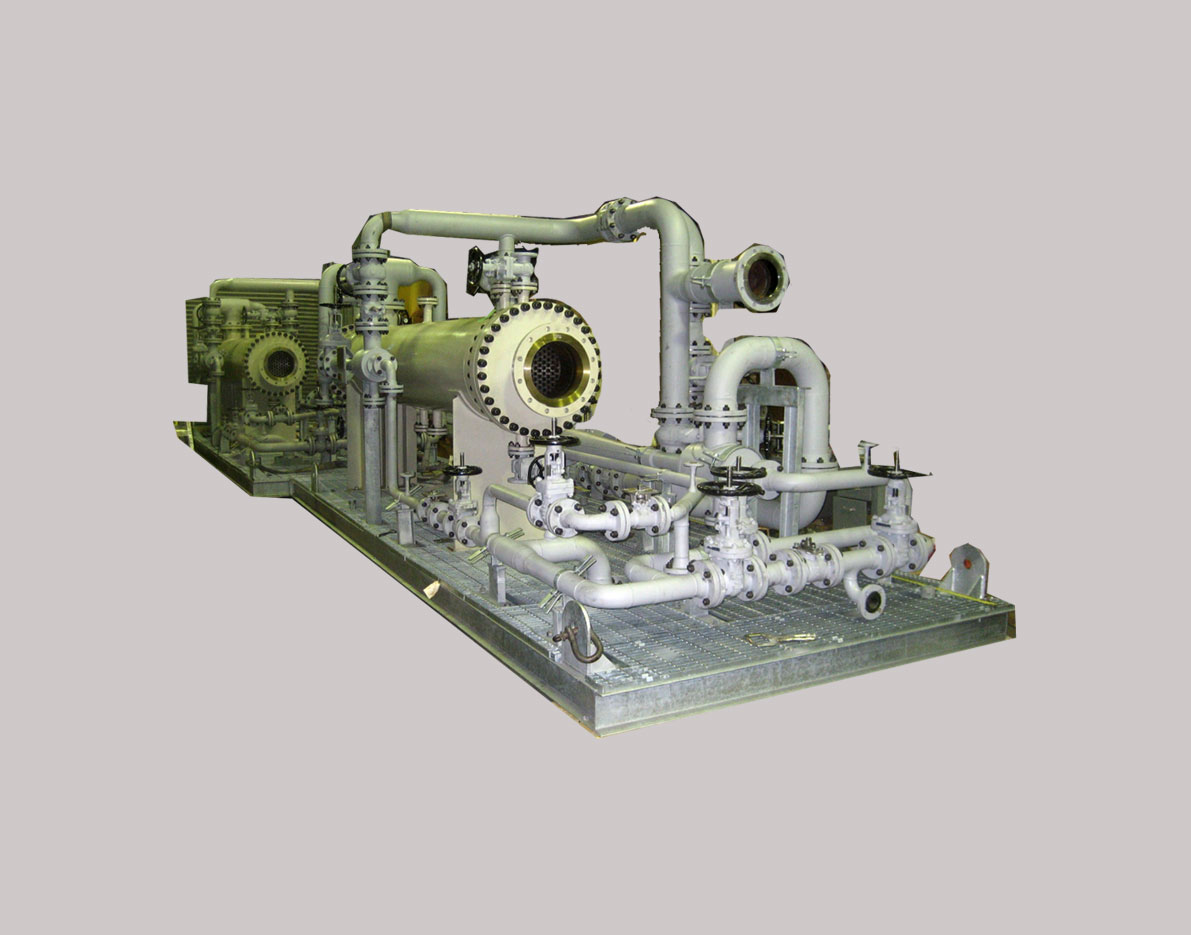

Croll Reynolds’ desuperheaters are designed for easy integration into existing steam systems. Their versatile construction allows them to be retrofitted into a wide range of industrial setups without requiring extensive modifications. The system can be built from standard steel, alloy, or high-alloy materials to match the specific requirements of the process, whether it involves high pressures, corrosive environments, or extreme temperatures. This flexibility ensures that industries across various sectors—including chemical processing, power generation, and food production—can benefit from efficient steam management while maintaining reliable, long-term performance.

Durability and Longevity

The robust construction of desuperheaters ensures durability and long service life, even in challenging industrial conditions. The lack of moving parts reduces mechanical wear, while the materials used in construction can withstand corrosive or abrasive process environments. This reliability translates to fewer interruptions, lower maintenance expenditures, and consistent output over many years of operation. By investing in a high-quality desuperheater from Croll Reynolds, industries can secure a dependable, long-term solution for controlling steam temperature and optimizing heat transfer processes.

Conclusion

Desuperheaters offer significant advantages for industrial processes by combining low maintenance, chemical-free operation, and substantial cost savings. Croll Reynolds has leveraged decades of engineering expertise to design systems that are simple, efficient, and adaptable to a variety of industrial applications. By ensuring that superheated steam is returned to its optimal, saturated state, these desuperheaters improve energy efficiency, reduce operating costs, and provide a reliable solution for modern industrial heat transfer challenges. For industries seeking to enhance performance while minimizing maintenance and environmental impact, Croll Reynolds desuperheaters remain an exceptional choice.