In the highly controlled environments of the chemical and pharmaceutical industries, maintaining precise process temperatures is not just a matter of efficiency—it’s a matter of compliance, safety, and product quality. With rising demands for cleaner technologies and energy-efficient systems, the choice of cooling equipment plays a critical role. That’s where vacuum chillers come in. These innovative systems offer chemical-free, energy-efficient cooling tailored to the rigorous standards of modern manufacturing. Croll Reynolds, a leader in engineered vacuum and steam systems, has been instrumental in bringing this technology to process industries around the world.

Clean, Contamination-Free Cooling

Both chemical and pharmaceutical operations demand exceptionally clean processing environments. Any form of contamination—especially from cooling systems—can lead to batch rejection, equipment corrosion, or regulatory violations. This is why clean cooling solutions are a necessity, not a luxury.

Traditional chillers often use chemical refrigerants or absorption fluids, which pose potential risks in sensitive manufacturing environments. By contrast, systems designed to cool using water and vacuum principles eliminate the need for chemical agents altogether. This ensures cooling without cross-contamination or hazardous byproducts—an essential requirement in pharmaceutical production lines or when manufacturing high-purity chemicals.

High Efficiency with Reduced Energy Use

Cooling accounts for a significant portion of energy consumption in most industrial plants. Energy savings, therefore, have a direct impact on profitability and environmental compliance. Systems that leverage vacuum principles to induce water evaporation under reduced pressure can achieve rapid cooling with minimal energy input.

In many facilities, steam is already available as part of the utilities infrastructure. Integrating a steam-powered cooling system makes strategic sense in such environments, enabling energy reuse and reducing dependency on electrically powered compressors or chillers. This shift not only improves energy efficiency but also contributes to a lower carbon footprint—a win for both plant economics and sustainability targets.

Reliability Through Simplicity

One of the defining features of non-mechanical cooling systems is their lack of moving parts. No compressors, no expansion valves, and no motors means there’s less to break down, wear out, or fail unexpectedly. In industries where downtime can be extremely costly, this reliability is a serious advantage.

For chemical and pharmaceutical operations that often run continuous production cycles or time-sensitive batch processes, this reliability provides peace of mind. When maintenance is required, it’s often simpler and faster, thanks to the modular design and mechanical simplicity of the system.

Support for Heat-Sensitive Processes

Cooling plays a critical role in reaction control, crystallization, condensation, and solvent recovery—especially in pharmaceutical applications where active ingredients must remain stable. Rapid temperature reduction is often required to avoid degradation or to complete a reaction step under precise thermal conditions.

The ability to cool water to temperatures in the low single digits, without exposing products to direct refrigerants or chemically treated cooling loops, makes these systems particularly well-suited for temperature-sensitive applications. With carefully engineered design and vacuum control, the temperature drop can be tightly regulated, helping manufacturers maintain consistent quality and throughput.

Engineered for Industrial Resilience

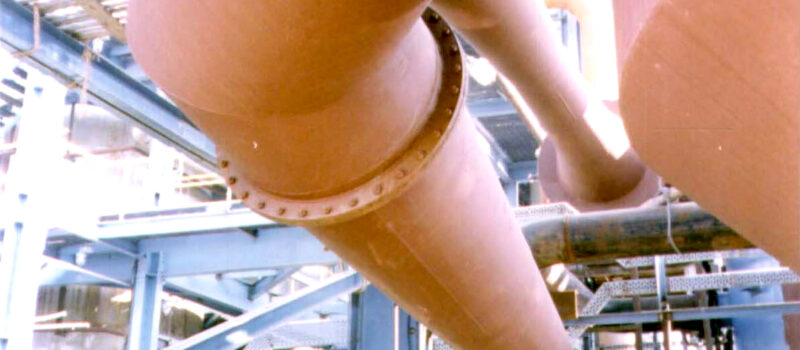

Chemical and pharmaceutical environments can be harsh. Equipment is often exposed to corrosive substances, cleaning chemicals, or high ambient temperatures. Cooling systems in these environments must be designed for durability and longevity.

What sets systems like those developed by Croll Reynolds apart is the flexibility in material selection. From stainless steel to high-alloy metals, systems can be customized based on process compatibility and resistance requirements. This ensures long-term resilience and compliance with the hygienic standards that these industries must uphold.

Seamless Integration with Existing Systems

The ability to retrofit cooling systems into existing infrastructure is often a deciding factor for plant engineers. Equipment replacement or system upgrades must minimize downtime and avoid costly overhauls. Modern engineered cooling systems offer modularity and adaptability, allowing them to be integrated into both legacy setups and greenfield installations.

Control and instrumentation compatibility ensures that these systems can work in concert with existing plant automation, allowing engineers to monitor performance, set parameters, and ensure that critical cooling thresholds are consistently met.

Enabling Sustainability Goals

As chemical and pharmaceutical manufacturers strive to meet corporate sustainability goals, reduce emissions, and prepare for future regulatory changes, cleaner cooling systems become an important part of the conversation. Technologies that eliminate refrigerants and minimize electrical load contribute directly to emissions reductions and improved ESG (Environmental, Social, and Governance) scores.

Sustainable manufacturing doesn’t have to mean compromising on performance. These cooling systems offer high-capacity performance while remaining aligned with cleaner and greener practices.

Conclusion

For manufacturers in the chemical and pharmaceutical sectors, precision, purity, and performance are non-negotiable. Cooling systems must align with these core needs while also supporting energy efficiency and regulatory compliance. Vacuum chillers meet this challenge by delivering reliable, chemical-free, and low-maintenance cooling suited for complex industrial environments. With decades of engineering expertise, Croll Reynolds continues to offer advanced solutions that help companies optimize their operations while supporting long-term sustainability and cost-effectiveness.