In many chemical and specialty process industries, creating vacuum without introducing steam, water, or mechanical complexity is a critical requirement. Traditional steam ejectors and mechanical vacuum pumps often bring challenges such as contamination, high maintenance, and energy losses. This is where the Process Powered Vacuum System stands out as an effective alternative. Designed for applications involving organic gases and vapors, this technology uses process fluids themselves to generate vacuum reliably and efficiently. At Croll Reynolds, these systems are engineered to deliver consistent performance while protecting product purity and reducing operational costs.

The Need for Steam-Free Vacuum Generation

Many fine chemical and polymer processes involve heat-sensitive materials or valuable vapors that cannot tolerate contact with steam or water. Steam-based vacuum systems can introduce moisture contamination, reduce product quality, and complicate downstream recovery. Mechanical pumps, while effective in some cases, contain moving parts that are subject to wear, corrosion, and frequent maintenance. A steam-free, non-mechanical approach to vacuum generation eliminates these risks, making it especially suitable for environments where purity, reliability, and low maintenance are essential.

Using Process Fluids as the Driving Force

Instead of relying on external utilities, a process-powered vacuum system uses high-pressure process fluids—such as organic liquids or gases—already available within the plant. These fluids act as the motive force for vacuum generation. By harnessing the energy contained in the process stream, the system converts existing pressure into useful vacuum without the need for additional power sources. This approach not only improves efficiency but also integrates seamlessly into existing process operations.

The Role of Ejector Technology

At the core of this vacuum system is ejector technology. An ejector is a static device with no moving parts, designed to create vacuum through fluid dynamics. High-pressure motive fluid enters a specially engineered converging-diverging nozzle, where its pressure energy is transformed into high velocity. As the fluid accelerates, the pressure drops significantly, creating a localized low-pressure region. This low-pressure zone is what draws in process vapors from the equipment or vessel that requires vacuum.

How the Jet Vacuum Principle Works

The jet vacuum principle governs the operation of the ejector. As the speed of a fluid increases, its internal pressure decreases. Inside the ejector nozzle, the motive fluid can reach sonic or even supersonic velocities. This rapid acceleration produces a strong vacuum effect in the suction chamber. Process vapors are entrained into the fast-moving motive stream, allowing them to be transported and compressed without mechanical assistance. This principle enables the system to achieve stable vacuum levels across a wide operating range.

Mixing, Compression, and Pressure Recovery

Once the motive fluid and suction vapors combine, they pass through the diffuser section of the ejector. The diffuser is carefully designed to slow down the mixed stream in a controlled manner. As velocity decreases, pressure increases, allowing partial recovery of pressure energy. During this transition, the flow may pass through a shockwave, shifting from supersonic to subsonic conditions. This controlled pressure recovery is essential for discharging the mixture at a pressure suitable for condensation or further handling.

Condensation and Vapor Recovery

After leaving the ejector, the combined stream typically enters a condenser where vapors are cooled and condensed. Because no steam is involved, valuable organic compounds can be recovered without dilution or contamination. This is especially important in processes where solvents or intermediates must be reclaimed for reuse or resale. The condensed fluids can then be pumped or transferred to the next stage of the process, while non-condensable gases are safely discharged. This integrated approach supports both operational efficiency and environmental responsibility.

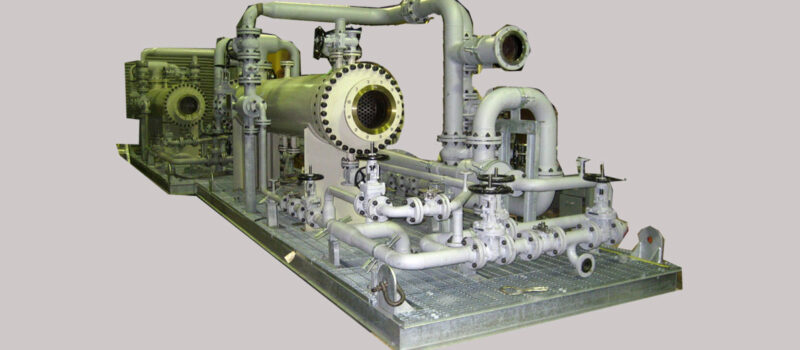

Reliability through Simplicity of Design

One of the most significant advantages of this vacuum approach is its mechanical simplicity. With no moving parts in the ejector itself, the system is inherently robust and resistant to mechanical failure. There are no seals, bearings, or rotating components to wear out over time. This results in lower maintenance requirements, reduced downtime, and longer service life. The system can also be constructed from a wide range of materials, allowing it to handle corrosive or high-temperature process conditions safely.

Adaptability across Vacuum Levels and Applications

Process-powered vacuum systems can be designed to operate at high, medium, or low vacuum levels depending on application needs. Multiple ejector stages can be arranged to achieve deeper vacuum when required. This flexibility makes the technology suitable for distillation, drying, flash cooling, polymerization, and other demanding chemical processes. Because the system relies on fluid dynamics rather than mechanical motion, it maintains consistent performance even under fluctuating process conditions.

Conclusion

By converting the energy of process fluids into vacuum, the Process-Powered Vacuum System offers a reliable, contamination-free solution for modern chemical processing. Its ability to operate without steam or moving parts makes it ideal for applications where purity, efficiency, and durability are critical. Through carefully engineered ejectors, controlled pressure recovery, and effective vapor condensation, this technology delivers stable vacuum while recovering valuable process components. With decades of expertise in vacuum and ejector systems, Croll Reynolds continues to provide engineered solutions that meet the evolving needs of fine chemical and specialty process industries.